PROCESS CHEMISTRY SUPPORT

Apeloa CDMO brings exceptional synthetic chemistry services to every customer project. Our experienced synthetic chemists design chemical synthesis routes with the end-product in mind, but appropriate to each stage of development. Process chemists from Apeloa work closely to craft and optimize robust synthetic routes to effectively scale up the development and manufacturing process. Apeloa CDMO’s scope of chemistries allows us to design complex routes using demanding and varied chemistry to achieve successful production. Fully supported by our state-of-the-art analytical services, Apeloa CDMO is your ideal partner for process chemistry services at any stage.

From the earliest stages of Active Pharmaceutical Ingredient (API) development, process chemists are responsible for designing the synthetic route that will maximize yield, enhance efficiency, and meet regulatory and safety requirements all while maintaining scalability of the synthesis route. The process chemist typically starts with the end molecule and works backwards through a sequence of reactions and purification steps to arrive at a viable chemical synthesis route. The quality of this synthetic chemistry route design impacts the product throughout its entire lifecycle all the way through scale-up and commercialization. Poorly designed, un-scalable, or unreliable synthesis routes can have a severely negative impact on the product and its likelihood of success.

WIDE RANGE OF SYNTHETIC CHEMISTRIES

Apeloa CDMO has the knowledge and capabilities to include a wide range of chemistry types in the design of customer synthesis routes. We have the knowledge and applied experience for a range of specialty technologies and chemistry types including:

- Fluorination (F2 & SF4)

- Chlorination/Bromination (Cl2 & Br2)

- Cyanidation (NaCN)

- Azidation (NaN3)

- Asymmetry reactions

- Grignard Reactions

- Hydrogenation

- Cryogenic Reactions (-78oC)

- Crystallization

- Flow Chemistry

- Bioproduction

We can develop complex chemical synthesis routes for specialized compounds including highly potent molecules or those with explosive or highly exothermic reactions.

SYNTHETIC ROUTE CONSIDERATIONS

Apeloa CDMO designs chemical synthesis routes appropriate for the stage of development. We do however, plan for the future success of customer molecules by designing synthesis routes that are largely scalable and efficient enough to produce a commercially viable yield.

At all stages of development, the following critical parameters are assessed by Apeloa CDMO scientists towards a successful outcome.

- Yield – maximize the yield of the overall reaction, while achieving desired purity

- Cycle Time – design route to minimize overall cycle time to make the process efficient

- Number of chemical steps and convergence – reduce complexity of the process when possible and shorten manufacturing timelines

- Safety – manage chemistry steps that pose risk to safety or reaction stability

- Energy-consuming operations – Design synthesis route options that minimize the consumption of energy for the environment and cost efficiency

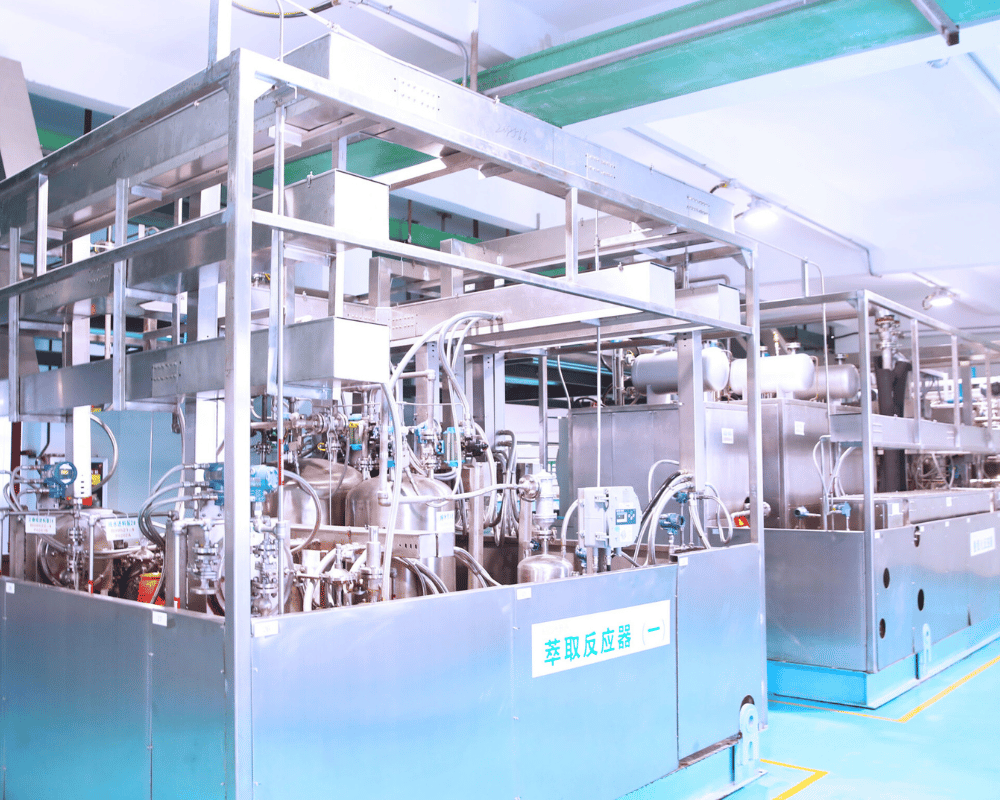

PILOT SCALE-UP

Apeloa CDMO applies designed synthetic routes using state-of-the-art pilot resources. At our Kangyu, Tospo, and Jiayuan manufacturing sites, located in Hengdian (China), as well as at our Shanghai R&D site, Apeloa has the capacity and capability to apply scale up procedures prior to large scale manufacturing. With a wide range of pilot reactor sizes (ranging from 3 L to 1,000 L), Apeloa CDMO can handle any scale up process to ensure optimal production is met.

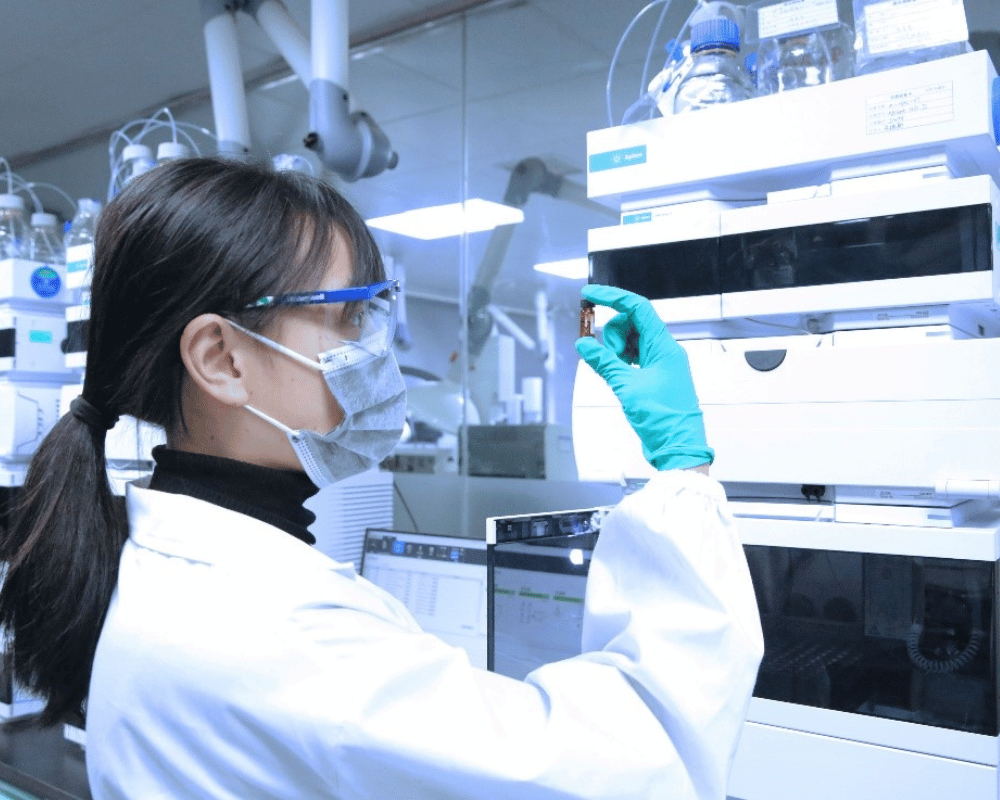

SCALEABLE FERMENTATION MANUFACTURING

Apeloa CDMO’s synthetic chemistry services are fully supported with our best-in-class analytical capabilities. With a full range of analytical capabilities, including Mass Spectrophotometry, HPLC/UHPLC, and other highly powerful analytical instrumentation, we take pride in fully characterizing the process every step of the way. From impurity identification and resolution to the qualification of materials as reference standards, we can perform your analytical testing needs in our modern laboratories and centralized analytical testing locations.