FLOW CHEMISTRY

Apeloa CDMO is highly experienced in flow chemistry synthesis at virtually any scale. With services from feasibility, process development and optimization (PD&O), and scale-up to commercial production, Apeloa CDMO’s state of the art facilities can meet your flow chemistry needs. Flow chemistry can offer distinct Active Pharmaceutical Ingredients (API) and intermediate synthesis advantages such as higher reaction speed, flexibility, scalability, and manufacturing safety.

Flow Chemistry is a relatively new technology that can be described as a process by which a continuous chemical reaction can be conducted in a moving stream of reagents rather than in a conventional batch reactor. Flow chemistry can deliver numerous distinct advantages over traditional batch reactions including

FULL LIFECYCLE SERVICES WITH FLOW CHEMISTRY TECHNOLOGY

Apeloa CDMO offers comprehensive flow chemistry expertise covering the entire lifecycle from compound development to manufacturing of intermediates and active pharmaceutical ingredients (APIs). Our capabilities cover everything from the earliest stages a performing a feasibility test, process development & optimization (PD&O), scale-up, commercial equipment screening and sample preparation all the way up to cGMP commercial manufacturing.

MULTI-LOCATION FLOW CHEMISTRY NETWORK

Apeloa CDMO’s flow chemistry technology services are supported by a number of locations across our multi-site global network facilities. The Boston (USA) site, launching in 2023, supports early phase discovery and preclinical services including lead optimization, BB library, research scale-up, ADME, and offers leading expertise in chemical technology platform and new modality chemistry development. Our flow chemistry laboratories in Shanghai and Hengdian (China) can efficiently develop gram to kilogram scale samples. Supported with the latest analytical instrumentation and skilled scientists, these sites can rapidly develop continuous synthesis routes that are fully scalable to meet any future demand. Our three pilot and commercial scale cGMP flow chemistry manufacturing sites are located in our Kangyu, Jiayuan, and Tospo sites (Hengdian, China). The flow chemistry production lines at these facilities can handle more than 10 kilotons of liquid per year, which can satisfy virtually any high-volume commercial production levels.

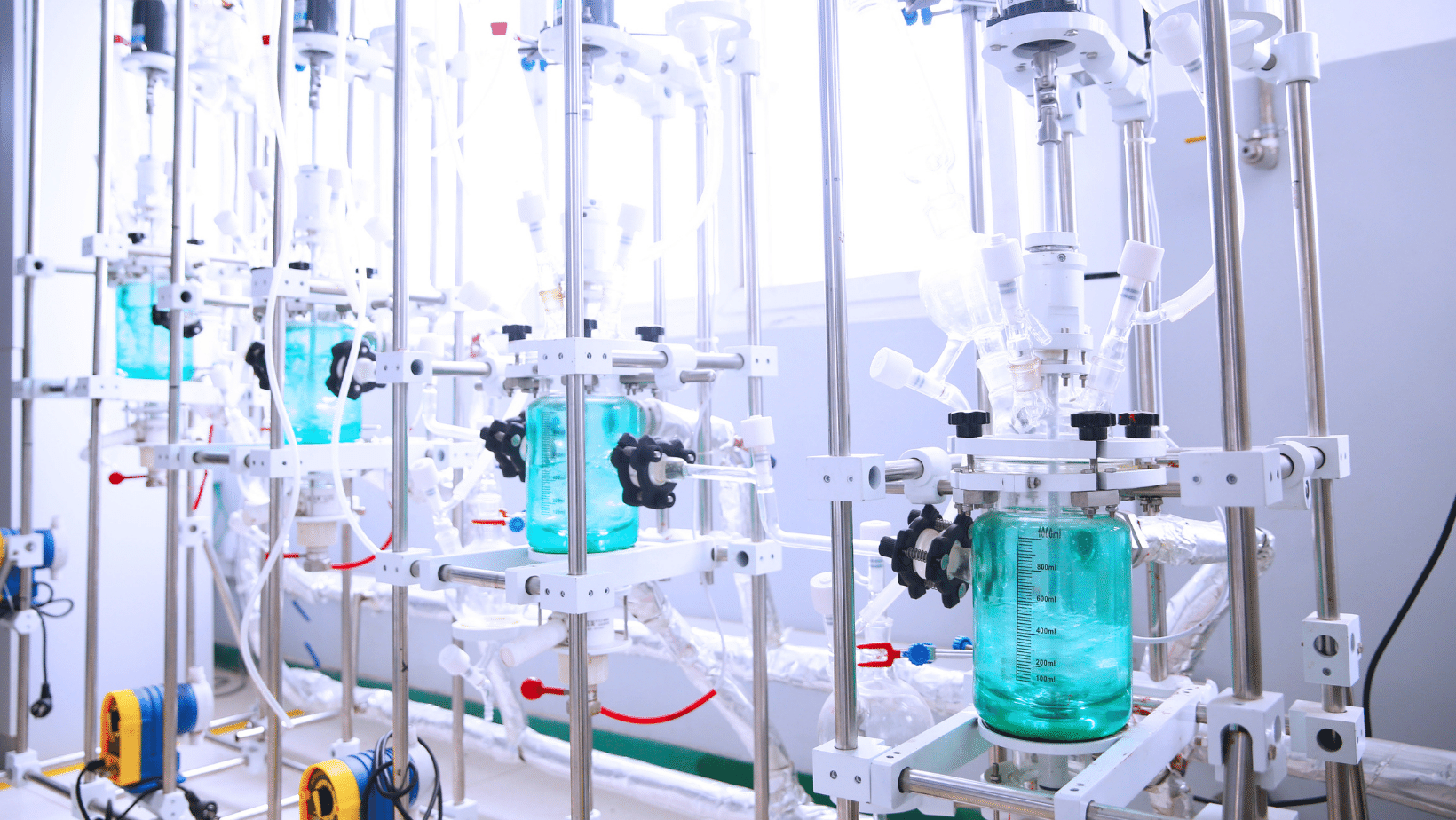

RANGE OF FLOW CHEMISTRY REACTORS

Apeloa has built a full complement of flow chemistry reactors for every scale and stage of development. Our flow chemistry R&D reactors are designed to seamlessly scale-up to our larger pilot and commercial scale reactors, ensuring rapid and efficient technology transfers.

Lab Scale Flow Reactors (g to 1kg scale)

- Micro reactors (Stainless steel, SiC, Hastelloy & Glass)

- Tubular reactors (Stainless steel and Hastelloy)

- Tangential reactors (Stainless steel and Hastelloy)

- Photo reactors (light) with tunable UV LED radiation and glass tubes

- Loop reactors

Our flow chemistry R&D reactors can handle G-L (gas-liquid), G-L-S (gas-liquid-separator), L-L (liquid-liquid), homo/heterogeneous reactions with stainless steel, Hastelloy (HC), Monel (nickel copper alloy), glass, and silicon-carbide (SiC) reactors. These reactors can handle flow rates ranging from 1ml/min to 1L/ minute depending on the volume of reactors and the required residence time of reaction.

cGMP Commercial Production Scale Flow Reactors (kg scale +)

Our pilot and commercial scale flow reactors range in capacity depending on reaction type and process parameters. We offer a full range of commercial scale flow chemistry capabilities that directly scale-up from lab scale reactors. We can apply Process Analytical Testing (PAT) tools to monitor intermediate and product quality supporting a continuous manufacturing approach.

- Microreactor

- Tubular Reactor (Monel)

- Tubular Reactor (Stainless steel 316L)

Our automated ring-opening reaction equipment offers a 70L equipment volume with a liquid capacity of 17kton/year.

FLOW CHEMISTRY REACTIONS

Flow chemistry can be an ideal approach for synthesis routes involving high risk conditions, such as highly exothermic, explosive, light activated, or highly complex multi-step synthesis routes. Our highly educated and experienced flow chemistry teams have worked with more than 20 flow chemistry reactions and over six products have scaled-up to commercial production. We have demonstrated scientific excellence with a wide range of flow chemistry reactions. Examples include azidation, hydrogenation, nitration, diazonium, ozonation, organolithium reaction, ring-opening, Curtis rearrangements, and Schiemann reactions.