HIGH POTENCY ACTIVE PHARMACEUTICAL INGREDIENT (HPAPI) MANUFACTURING

Apeloa CDMO are experts in the manufacturing of highly potent Active Pharmaceutical Ingredients (HPAPIs). Our high-potency facility is dedicated to the development and manufacturing of highly potent compounds and use appropriate containment, controls, and management systems to ensure worker safety. Apeloa-CDMO has developed comprehensive EHS and safety systems combined with leading edge manufacturing suites using isolator and segregation technologies to deliver high-quality products. With the capability to safely produce a range of highly potent molecules in virtually any scale, Apeloa CDMO is an ideal partner for contract Highly Potent Active Pharmaceutical Ingredient (HPAPI) manufacturing.

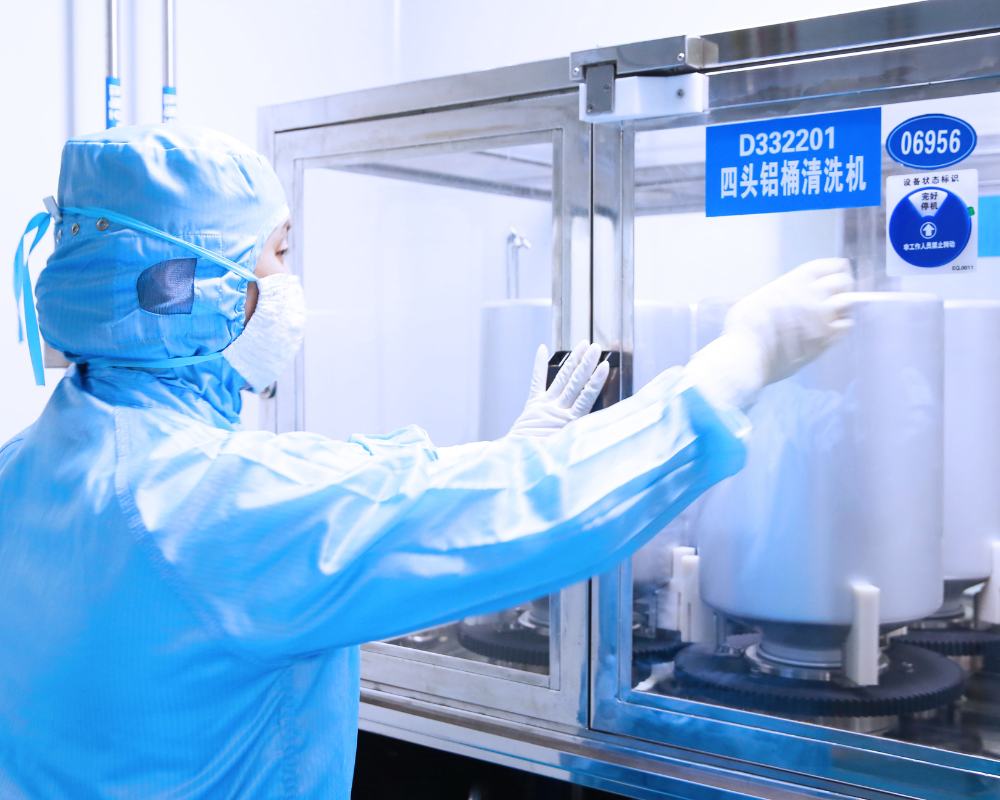

DEDICATED HIGH POTENCY API (HPAPI) MANUFACTURING FACILITY

Apeloa CDMO built its Highly Potent Active Pharmaceutical Ingredients (HPAPIs) facilities to meet the strict Environmental Health and Safety (EHS) and regulatory requirements of the pharmaceutical industry. As our facilities support multiple products, self-contained bays prevent cross-contamination with other products and help to ensure worker safety. Our HPAPI manufacturing facilities consist of over six bays which are all separate closed systems hosting a total reactor volume of 75 m3. Three of the bays are designed to produce Registered Starting Materials (RSMs) and Intermediates rated up to OEB-4. There are several additional bays designated for the manufacture of Highly Potent Active Pharmaceutical Ingredients (HPAPIs) up to a rating of OEB-5.

Our various segregated bays offer reaction, purification, filtration, washing & drying as well as some with crystallization, filtration, and grinding capabilities. Our high potency API facilities are also equipped with a range of dedicated equipment to support production including distillation units, filter driers, conical driers (2000L HC22), horizontal scraper centrifuges (HC22), static tray ovens, and jet mills and hammer crusher equipment for grinding.

WORLD CLASS HPAPI SAFETY SYSTEMS

Apeloa CDMO has developed a rigorous high-potency management system to ensure the safe handling and containment of Highly Potent Active Pharmaceutical Ingredients (HPAPIs) within our state-of-the-art facilities. Our scientists and EHS staff carefully assess incoming drug substances or their intermediates for toxicity, Occupational Exposure Levels (OELs), and other risk assessment procedures in order to define the necessary controls required to manage every step of the synthesis. Apeloa CDMO deploys isolator technologies in the suites to limit exposure of potent compounds at every stage of the manufacturing process. Our staff use advanced cleaning methods that are verified by analytical testing to ensure all contact equipment is clean and free of contamination post-use, to avoid any risk of cross contamination.

HPAPI DEVELOPMENT SERVICES

Apeloa CDMO takes a cautious approach to the development of new compounds that may prove to require high-potency handling. With careful and thorough assessment of incoming molecules for toxicity, OEL, and risk, Apeloa CDMO’s skilled EHS and technical teams design development programs utilizing appropriate containment, personal protective units (PPUs), and monitoring programs. We utilize small scale reactors with appropriate controls and containment which can be rapidly scaled to larger reactors within our specialized high-potency facility.

HPAPI ANALYTICAL LABORATORY

With a 400 m2 analytical laboratory dedicated to development and testing of Highly Potent Active Pharmaceutical Ingredients (HPAPIs), we can quickly and safely analyze highly potent compounds rated up to OEB-5. Utilizing our modern qualified analytical instruments and specially trained analysts, Apeloa CDMO can efficiently quantify, test, or validate test methods developed for highly potent molecules.