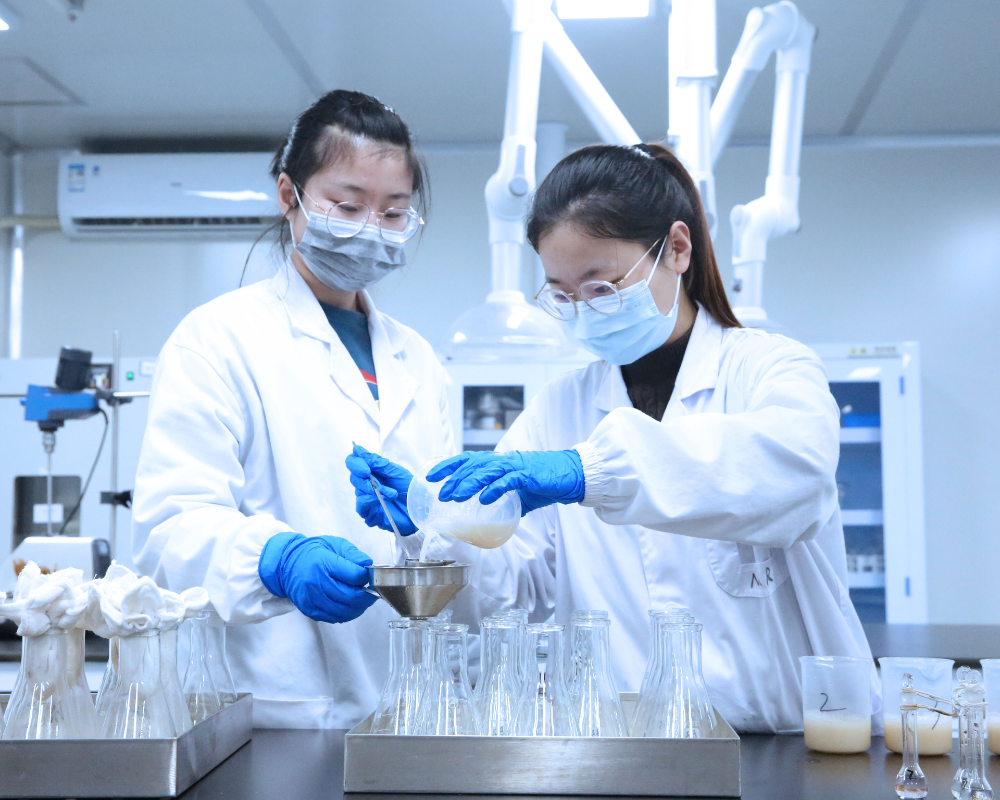

FERMENTATION TECHNOLOGY PLATFORM

For over 20 years, fermentation capabilities have been a key part of our bio-production technology platform. Fermentation utilizes living microorganisms to efficiently produce a wide range of Active Pharmaceutical Ingredients (APIs), intermediates, and starting materials for products such as amino acids, antibiotics, statins, antifungals, and intermediates. With fermentation reactors from early development scale to commercial, Apeloa CDMO employs a dedicated team working between two of our state-of-the-art facilities to deliver industry leading contract services for our customers.

ESTABLISHED FERMENTATION TEAM & FACILITIES

At Apeloa, we have a very experienced fermentation team of over 60 scientists and engineers and two modern production sites hosting over 150 fermentation reactors. More than half of our staff have master’s degrees or higher, and are dedicated to advance your material development or production. Our fermentation reactors are stainless steel in construction and range in size from 500 to 120,000 L each, providing a full range of production from mg to ton scale. We aim to assist our customers in developing various types of fermentation products, including Regulatory Starting Materials (RSMs), Intermediates, and APIs.

Anhui Apeloa Biotech (cGMP)

Facility Area: 583,000 m²

Fermentation Capacity: 1,920 m3

Zhejiang Apeloa Biotech (cGMP)

Facility Area: 141,000 m²

Fermentation Capacity: 3,232 m3

SPECIALIZED FERMENTATION CAPABILITIES

Apeloa CDMO has extensive experience with microbial fermentation using bacteria, fungi, and actinomycetes. With a full range of fermentation technologies and approaches we provide the right solution for your bio-production needs. We have significant fermentation experience with both process development and cGMP production of a full range of products such as amino acids, antibiotics, and pharmaceutical intermediates. Our customized bio-catalysis process is a cost efficient and environmentally friendly route to making expensive chiral molecules via stereoselective biotransformation. We also offer enzyme screening, enzyme evolution, and bioprocess development.

Animo Acid Synthesis Approaches

- Classic resolution

- Asymmetric hydrogenation

- Enzymatic catalysis

Commercial Fermentation Product Experience Examples

- L&D-Serine (500 MT/year)

- L&D-Phenylalanine (60 MT/year)

- L-Phenylglycine (500MT/year)

Apeloa CDMO has the experience and capabilities to develop or manufacture a wide range of RSMs, Intermediates, and APIs using fermentation.

BIO-PRODUCTION TECHNOLOGY PLATFORM

Apeloa CDMO has developed a comprehensive bio-production technology platform to support the development of efficient and robust cGMP compliant bio-production processes.

Microbial Strain Development

Microbial strain improvement can greatly impact the efficiency and cost of the fermentation process when scaled up at production. Apeloa CDMO employs genetic engineering and mutagenesis of the microbial strain to improve fermentation process outputs. This step can include the use of a high throughput shaker (sample vortexer) or ARTP mutation (atmospheric and room temperature plasma) allowing genetic mutations.

Fermentation

The Fermentation process is further optimized using the improved microbial strain. With over 7,500 m3 of fermentation reactor capacity and Mass Spectrophotometer (MS) tail gas analysis capabilities, we maximize the reliability and efficiency of the fermentation process.

Separation

Downstream Processing (DSP) from fermentation is designed to achieve the highest purity and quality of product possible. Experience and know-how in separation processes allows Apeloa CDMO to seamlessly scale up bioproduction directly to a cGMP production process. We utilize freeze drying and spray drying methods and industrial preparative chromatography (DAC 50-100) to isolate your material.

Biotransformation

Biotransformation at Apeloa CDMO uses enzyme screening and evolution to further optimize the process. Passing through a microfiltration membrane, a high-pressure homogenizer, and nanofiltration membrane can help to transform the molecule to the desired output.

SCALEABLE FERMENTATION MANUFACTURING

Apeloa CDMO develops its bio-production processes, including fermentation, to be scalable to commercial scale production. Our knowledgeable fermentation scientists and engineers can start to develop custom processes at the lab scale, using modern equipment in two state of the art facilities and bring them quickly to cGMP production in as large as metric ton scale.