CORE CHEMISTRY

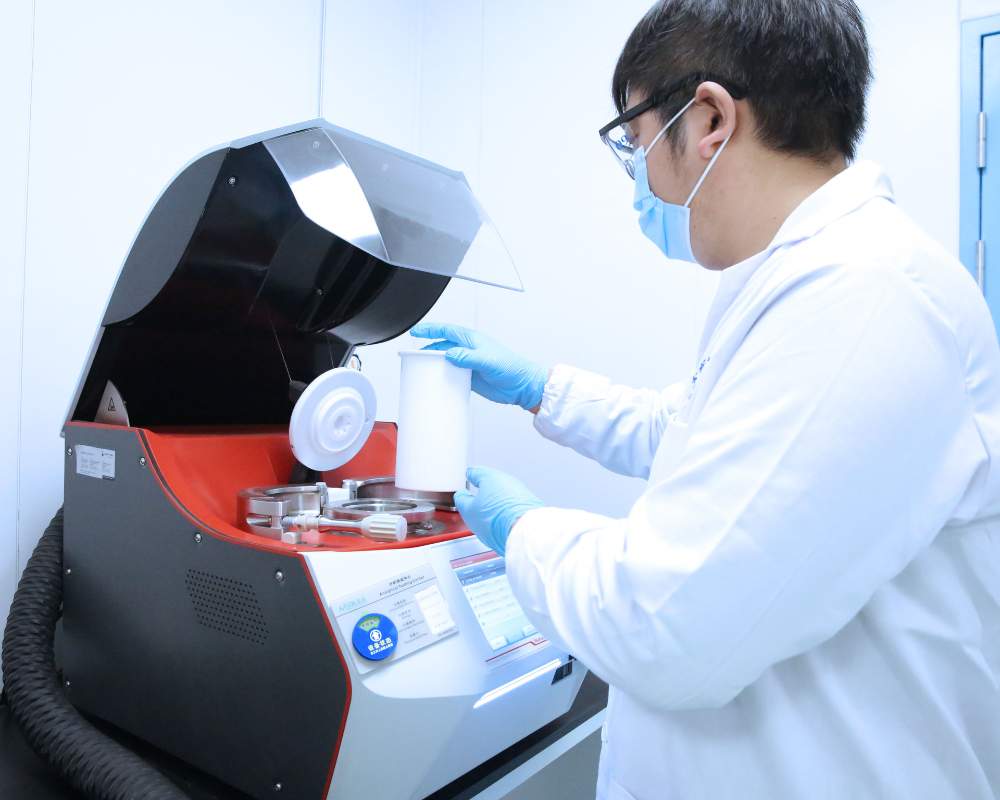

Apeloa CDMO offers a wide range of core chemistries and technologies, with capabilities to develop and manufacture a wide range of molecules at the highest quality. With over 20 years of experience with different synthesis routes and technologies, Apeloa CDMO has developed specialized capabilities allowing for the use of leading-edge technologies including Fluorination, Azidation, Asymmetry, Grignard reactions, Hydrogenation, Cyanidation, and Cryogenic reactions. Our vast experience, modern facilities and reactors, complete in-house analytical support, and attention to quality requirements, allows Apeloa CDMO to be a responsive partner for your contract regulated starting material (RSM), intermediate, and API needs.

The manufacture of starting materials, intermediates, and Active Pharmaceutical Ingredients (APIs) can utilize a wide range of complex chemical and biological processes in order to efficiently produce the desired molecules. This requires a wide range of equipment such as chemical or biological reactors, analytical support, quality systems, and technical know-how to produce materials suitable for the high standards required by today’s pharmaceutical industry. Apeloa CDMO offers all of these elements to its contract customers around the world, reliably producing molecules at virtually any scale using a wide range of core chemistry processes or technologies.

WIDE RANGE OF CORE CHEMISTRIES

Apeloa CDMO has developed a comprehensive offering of contract core chemistries that can produce the complex and high-quality starting materials, intermediates, and Active Pharmaceutical Ingredients (APIs) needed by today’s pharmaceutical industry. Our experience and capacity allow us to utilize everything from well-established synthesis steps to innovative leading-edge chemistries, which are fully supported and manufacturable in our state-of-the-art network of 13 global development and manufacturing facilities. Some of the core chemistries offered by Apeloa CDMO include:

- Fluorination (F2 & SF4)

- Chlorination/Bromination (Cl2 & Br2)

- Cyanidation (NaCN)

- Azidation (NaN3)

- Asymmetry reactions

- Grignard Reactions

- Hydrogenation

- Cryogenic Reactions (-80oC)

Apeloa CDMO’s core chemistry capabilities cover everything from early-stage development and feasibility, product development & optimization (PD&O), and scale-up to full scale cGMP commercial manufacturing.

MANUFACTURING CAPACITY

Apeloa CDMO has built substantial chemical synthesis capacity across its network of facilities. With development services available in Boston (USA), Pudong Shanghai (China), and Hengdian Zhejiang (China), as well as five chemical API manufacturing sites in China, Apeloa CDMO has the capacity to supply your molecules at the required scale, fast, and to the highest quality. Our cost-efficient manufacturing sites help us deliver competitive pricing along with responsive timelines and 1–2 weeks airfreight delivery of products.

Apeloa CDMO Capacity Statistics:

- >10,000 m3 of total reactor capacity

- >1,800 total reactors

- 50 – 45,000 L reactor sizes

- 3,000+ Metric tons/year API capacity

- 25,000+ metric tons/year Intermediates capacity

With reactors including those constructed with stainless steel, glass-lined, Hastelloy, titanium alloys, Monel, and Teflon contact materials, Apeloa CDMO has the chemical capacity to produce virtually any molecule at scale.

QUALITY AND REGULATORY EXCELLENCE

Our quality systems are regularly audited by major regulatory agencies, including the U.S. FDA, EDQM (EU), and the PMDA (Japan). These regulatory bodies have successfully inspected our facilities over 25 times, most recently in 2022. Our manufacturing sites hold GMP and ISO certifications and we are experienced in the preparation and submission of regulatory dossiers (ASMF, CEP, DMFs). Our contract services can include comprehensive CMC support including the provision of data in submission-ready formats. Apeloa CDMO maintains these high levels of regulatory compliance so that customers can have confidence that the products we produce for them meet the highest quality standards.

FLEXIBLE AND FAST DELIVERY

Apeloa CDMO’s flexibility and responsiveness to customer needs is what makes us stand apart from the competition. Our ability to take in new contract projects, perform in-depth but rapid intake assessments, complete tech transfers and/or process development, and bring the product safely to manufacturing is only possible because of our combination of people, capacity, experience, and customer service focus. Apeloa CDMO is an international shipping expert, with 1-2 week logistics options by airfreight under flexible DDP, DDU & CIF (Incoterms) delivery terms.

INTEGRATED DEVELOPMENT SERVICES

Our Core Chemistry contract services are fully supported by our R&D and analytical services groups. Apeloa CDMO’s R&D groups in Boston (USA), Pudong Shanghai (China), and Hengdian Zhejiang (China) offer integrated development services that can take your molecule from an idea to manufacturing. With medicinal chemistry, synthetic chemistry, and our PROTAC capabilities we can act as your research arm and determine an effective and robust synthesis route to produce your new molecule. Apeloa CDMO also has grown its analytical services to be able to fully support these development requirements and develop/validate analytical methods that characterize the product as they move into manufacturing.